Choosing the Right Bead Mill Homogenization Technology for Your Laboratory

May 2, 2022Bead mill homogenization is a fast technology for automatically preparing a wide variety of samples – up to 96 in 30 seconds without cross-contamination, allowing you to spend more time on experiments, analysis and publishing.

HOW BEAD MILL HOMOGENIZATION WORKS

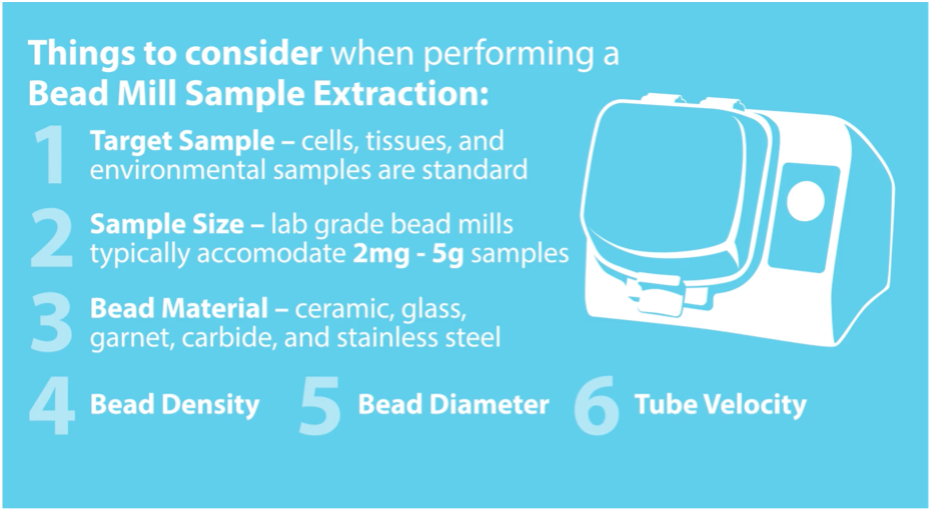

Bead homogenization works by using rapidly accelerating beads of various sizes and compositions within a sealed tube to dissociate a sample upon impact. Upon repeated impact with the beads, the cellular and connective tissue breaks down to release analytes. Human, animal and plant samples with any hardness level can be quickly homogenized, in batches of just a few samples up to about 100 samples concurrently – in as little as 30 seconds. From the extraction of protein from soft tissues, to the extraction of analytes from hard tissue including muscle, skin and bone, bead homogenization is a fast and robust method for grinding, lysing and homogenizing the most challenging biological samples.

Bead Selection

The softest beads, made of silica, are helpful in breaking down tissue or microorganisms. The hardest beads, made of garnet, are the hardest and most robust for breaking down DNA.

The softest beads, made of silica, are helpful in breaking down tissue or microorganisms. The hardest beads, made of garnet, are the hardest and most robust for breaking down DNA.

SILICA

This bead is the least aggressive due to its low density, hardness and generally spherical shape. Silica is used primarily for disrupting microorganisms.

CERAMIC

This bead offers higher density and strength than silica and is chemically inert so it will not bind nucleic acids. Ceramic is useful for:

- 0.1mm: bacteria, mammalian and fungal cells, and use in 96 well plates

- 0.5mm: gram positive bacteria, mammalian and fungal cells, and use in 96 well plates

- 1.4mm: soft tissues, brain, liver, kidney, spleen, and soft plant material

- 2.8mm: hard tissues, heart, muscle, skin, tendon, tail, whole organs, and hard plant material

- 6.5mm: dry grinding applications, grains, seeds, and lyophilized hard plant material

Silica

This bead is the least aggressive due to its low density, hardness and generally spherical shape. Silica is used primarily for disrupting microorganisms.

Ceramic

This bead offers higher density and strength than silica and is chemically inert so it will not bind nucleic acids. Ceramic is useful for:

- 0.1mm: bacteria, mammalian and fungal cells, and use in 96 well plates

- 0.5mm: gram positive bacteria, mammalian and fungal cells, and use in 96 well plates

- 1.4mm: soft tissues, brain, liver, kidney, spleen, and soft plant material

- 2.8mm: hard tissues, heart, muscle, skin, tendon, tail, whole organs, and hard plant material

- 6.5mm: dry grinding applications, grains, seeds, and lyophilized hard plant material

Carbide

A relatively low-density bead with high strength and hardness, making it ideal for RNA extraction from micro-organisms, soil and sediment.

Glass

Low density and less durable beads that are cost-effective, inert but can be modified or derivatized using silane chemistry, and can be used in combination with other bead materials to reduce shearing intensity. Glass beads are ideal for:

- 0.1mm: RNA extraction from micro-organisms, soil and sediment

- 0.5mm: tough micro-organisms, gram+, yeast, fungi, algae, spores and plankton

Zirconium Silicate

Higher in density than glass but lower than stainless steel and zirconium oxide, zirconium silicate beads can be partially modified or derivatized using silane chemistry.

Zirconium Oxide

A material with high density, durability, and hardness, zirconium oxide can break very tough and hard samples, including organisms with a dense exterior matrix. To increase hardness, density, and durability, zirconium oxide beads can be yttria-stabilized or ceria-stabilized.

Stainless Steel

The hardest and most dense of all material types, stainless steel beads generate high impact with minimal shearing and are ideal for:

- 2.4mm: hard tissues, dry grinding, skin, muscle, bone, hair, roots, and seeds

- 5.0mm: processing in well plates (not compatible with 0.5 – 50 ml tubes)

Garnet

This bead is highly aggressive, making it very robust for:

- 0.15 and 0.7mm: soil, clay, sediment, waste water, and feces

Cannabis Homogenization

Among the most difficult of samples to homogenize, cannabis leaves and edible cannabis products like gummies, contain oils that can leave samples homogenized by other methods tarry and inconsistently reduced. Bead homogenizers, which can be customized by the type and size of bead, are an effective and consistent way to prepare medicinal or recreational cannabis samples for analysis. As both a medicinal, food, and an agricultural product, cannabis must be tested to for potency, and safety, including analysis to detect pesticide or microbial contamination. Other applications include preparation of samples for DNA extraction.

Bead milled homogenizing offers a rapid cell lysis method to break down both plants and edible samples for laboratory testing.

Ceramic beads are commonly used for agitating cannabis flowers in a laboratory homogenizer. Other varieties of bead media are available depending on the density and elasticity of the material being homogenized.

Advantages of Bead Mill Homogenization

In addition to the ability to customize the bead media, bead mill homogenization brings other advantage to the process:

- The ability to process a wide range of sample types, including both liquid and solid samples

- The ability to process multiple samples simultaneously

- Front loading, pre-filled, sealed tube homogenizers minimize clean-up and the risk of cross-contamination

- Sealed tubes reduce the risk of samples becoming aerosolized

Two Key Bead Mill Features

Labs cannot tolerate cross-contamination. This is particularly dangerous when your samples contain infectious agents. This is why it’s critical to choose a bead mill homogenizer with a properly sealed chamber (especially if a test tube breaks).

Top-loading bead mill homogenizers tend to increase the possibility of leaks, make it harder to see and access your samples. Front-loading bead mill homogenizers further minimize leak risks and it’s easy to see and access your samples so you don’t miss something.

About OMNI International Bead Mill Homogenizing Technology

OMNI International can provide your lab with the best fit bead mill homogenizer technology to automatically prep your samples. We can also process a sample for you in our in-house lab at no charge – we’ll even send you a report with photographs so you can evaluate the effectiveness of our bead mills.

From the compact design of the Bead Ruptor 4 to the advanced automation of the Bead Ruptor Elite, we offer powerful homogenization solutions and tools that combine state-of-the-art digital controls and ease-of-use, whether you are processing just a few samples at a time or up to 384 samples per cycle.

Since 1954, OMNI International has provided high-quality, trouble-free homogenizers to laboratories worldwide. OMNI products are designed and built in the United States under ISO 9001 Quality Management Standards.

www.omni-inc.com/contact-us for more information, to arrange a demonstration or to request processing of your sample.

For research use only. Not for use in diagnostic procedures.