About us

Who We Are

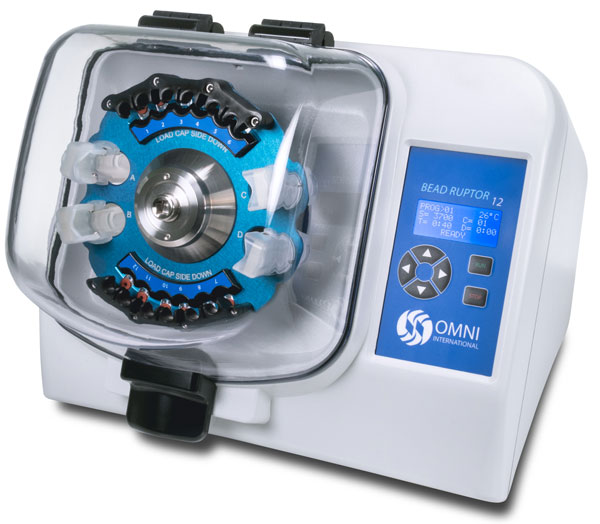

Omni International, Inc, with headquarters in Kennesaw Georgia, is a leading global manufacturer and distributor of laboratory homogenizers. Omni sets the industry standard with an unmatched commitment to outstanding product design, reliable performance and a uniquely diversified solution based product line.

Since 1956, the name Omni has been synonymous with laboratory homogenizers. Referenced in over 10,000 peer reviewed scientific articles, Omni International homogenizers can be found in laboratories worldwide and are counted on for years of trouble-free operation.

Omni products are designed and built in the United States under ISO 9001 Quality Management Standards.

Our Mission

Empower Scientists to Focus on Discovery and Innovation by Simplifying Sample Prep Workflows

Our Core Values

- Innovate

- Understand

- Collaborate

- Empower

- 1956

- 1960

- 1984

- 1989

- 1992

- 1993

- 1994

- 1995

- 1999

- 2003

- 2005

- 2010

- 2011

- 2013

- 2016

- 2018

- 2020